great question - but most likely is it almost impossible to have a "logic board repair guide" for the masses.

it's not about the electrical engineering degree or the eqipment you would need to do anything with component level repair.

anybody can learn anything and buying some tools should not be too hard (but it could be very expensive)

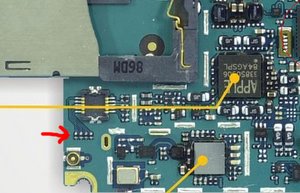

here is an example for the actual repair - not the diagnostic stuff

those 4 parts are pretty tiny - never forget that some people aren't able to connect cable 5 & 6 on the iphone (those parts are between connector 5&6)

here are a few problems you might have with this board

the use of a smd soldering iron is almost impossible - the parts are to tiny and even a new smd solderind tip is too big

so it must be hot air or infrared - since the plastic parts are very delicate - you have to be pretty careful with the temperature

the underfilled chips must stay "cool" - if they get to hot - the molten solder will crack the underfilling and the board will be dead

ahh - btw, did i mention that each of the 4 parts is tiny - the length is approx less than 1mm (no, i'm not kidding).

using a microscope and a tiny smd tip could be an option, but soldering under the microscope is not an option for me - the needed microscope will cost a fortune - and i hated it (worked as a nokia service tech).

ok, next problem - parts of that size will stick even on anti-magnetic tweezers or your fingertip and if they fall down - you will most likely never find it

that might look extreme - but it isn't - if you do component level repair - it's pretty much "common"

surely - notebooks are larger that smartphones - but the used parts are getting smaller and many computers are using the same small parts like shown above.

another thing is the actual repair guide - for a regular user almost impossible to handle

first of all - you need photos - but thats a problem, if someone has the equipment, the knowledge and a victim to dissect (you might think that this would be enough) - and a extremely good dslr with an expensive macro lens and a white table and some pretty good lights (light, even if you think that it would be enough, it's most likely not) - and of course - someone who is able to take good pictures of the things you're doing on the board.

(yes - i know that ifixit would have all the things - but in my case - i'm a "few" miles away from them)

component level repair is pretty heavy stuff, many "professionals" won't do everything - even if they do that for living.

check the ylod questions here on ifixit - you can have the tools, there is a guide and even with a good guide and the working tools - some users are not able to fix the problem.

it's not the inability of the user, a bad guide or bad tools - sometimes it won't work, sometimes it's the wrong temperature, the wrong duration - the wrong anything.

i started component level repairs in 1999 (only for fun) - i do thing's without a "repair guide" or an oscilloscope - but that limits the repair possibilities. most of the time i work on cellphones - there are some "service manuals" in the wild - but that won't help you if you can't buy the parts - some fixes are a little bit like a "texas chainsaw massacre" - but they work. there are many pages where you only get a picture of the pcb with a few lines on it - that's it.

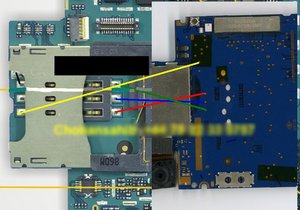

like this

any idea what this means??

this is the "pinout" of the iphone 3g/3gs sim card reader - most likely the last resort to fix a faulty card reader(logicboard related)

there are a few internet pages with that kind of guerilla repair.

but that's not an option for the regular ifixit user - most of the time, it's the last thing you could try. some of those "repairs" are like brainsurgery with a kitchen knife - and that's something i won't see promoted here - it comes from the "underground" and it should stay there (most of the time ;-) )

wow - that's a pretty long text and i hope that it's not to chaotic - lol

3

3  1

1

1

1

1 Comment

i've heard of people repairing logic boards that don't have a electrical engineering degrees and the bottom line is that it would be useful to actually have resources or videos on people repairing them, just the basics and i have looked on the web many times at resources and all turn back nothing. Even the tool list and what to do the board would be useful to anyone. I would hate to even take it to a person that has a $250 flat rate service when maybe the repair could be as simple as a dollar. Apple does not release diagrams on the logic boards because they want you money and want to do the easy fixes. Any insight on apple logic board resources of damages would be helpful.

One of you engineers have to want to give away the secret behind it all!?!?

by Josh Corson