Wish list: Skinny 1/4" driver extension

Every decent 1/4" driver set has one of these extenders:

I have at least three.

But domestic and kitchen equipment often has deeply recessed security screws and those extenders can be too fat for the recess holes.

I got myself a 50 piece set of 60mm 1/4" security bits but they're not always long enough. And I really notice their weight in my tool bag when I go to a repair event.

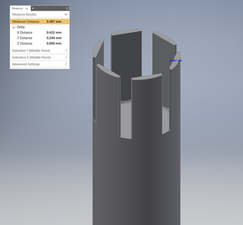

What I'd really like is an extender no wider than the diagonal width of a 1/4" bit (around 7mm, chamfered).

A 1/4" shaft with 6 hardened steel fingers on the end to grip the bit is what I have in mind. And for the cherry on the cake, how about a good strong neodymium magnet amongst the fingers to magnetise the bit and pull that pesky screw out of its hole?

So how about it, iFixit? And while you're at it, a similar 4mm extender might just come in handy too.

Regards - Philip

Is this a worthwhile discussion?

7

7  3

3

2 Comments

@pleriche I'd buy a few of those myself ;-) BTW great job with the The Restart Project and RepairDay!!!!

by oldturkey03

I'm currently looking everywhere for 6" long 5/32 (4mm) tips, I can find 6" long 1/4" shafts all over the place. (https://www.amazon.com/dp/B00MMQL6UI) Let me know if you find any that are the precision toolkit size. Extensions will always have this issue as the item allowing the extension has to be larger than the bit.

by Terry Schulte